MCC Cone Crusher

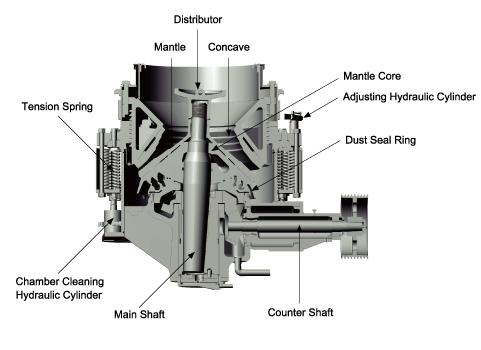

There are generally four types of Standard Cone Crushers: the MCC Standard or Coarse type, the MCF Fine or Medium type, the MCS Short Head type & MCSS Super Fine type. All four types are designed for secondary or tertiary crushing purposes both in stationary and portable applications for highly abrasive materials.

Features:

- The spring-loaded release system allows any uncrushable material to pass through without causing any damage.

- The lubrication unit is interlocked with the main motor for additional safety as a standard equipment.

- A rib liner is provided inside the bottom section of the frame to help protect it from wear.

| Model No. | Size (in/type) | Max Feed Opening (in/mm) | Min Discharge Opening (in/mm) | Rotation (RPM) | Motor Power HP (kW) | Weight (lbs/kg) |

|---|---|---|---|---|---|---|

| MCC600 | 24 / Coarse Liner | 3 3/4in / 95mm | 7/16in / 10mm | 630 | 50-60 / 37-45 | 11,660 / 5,300 |

| MCF600 | 24 / Fine Liner | 2 3/4in / 72mm | 1/4in / 6mm | 630 | 50-60 / 37-45 | 11,660 / 5,300 |

| MCC1000 | 40 / Coarse Liner | 6 1/2in / 160mm | 1/2in / 13mm | 630 | 120-150 / 90-110 | 23,760 / 10,800 |

| MCF1000 | 40 / Fine Liner | 4 1/2in / 115mm | 7/16in / 10mm | 630 | 120-150 / 90-110 | 23,760 / 10,800 |

| MCS1000 | 40 / Short Head | 3in / 80mm | 5/16in / 8mm | 630 | 120-150 / 90-110 | 23,122 / 10,510 |

| MCSS1000 | 40 / Ultra-Fine Shorthead | 2in / 50mm | 1/4in / 6mm | 630 | 120-150 / 90-110 | 23,122 / 10,510 |

| MCC1150 | 45 / Coarse Liner | 7in / 180mm | 1/2in / 13mm | 610 | 150-175 / 110-132 | 29,773 / 13,533 |

| MCF1150 | 45 / Fine Liner | 5in / 130mm | 7/16in / 10mm | 610 | 150-175 / 110-132 | 29,773 / 13,533 |

| MCS1150 | 45 / Short Head | 3 1/2in / 90mm | 7/16in / 10mm | 610 | 150-175 / 110-132 | 29,773 / 13,533 |

| MCSS1150 | 45 / Ultra-Fine Shorthead | 2 1/2in / 60mm | 1/4in / 6mm | 610 | 150-175 / 110-132 | 29,773 / 13,533 |

| MCC1300 | 51 / Coarse Liner | 8in / 200mm | 5/8in / 16mm | 610 | 175-215 / 132-160 | 49,060 / 22,300 |

| MCF1300 | 51 / Fine Liner | 6in / 150mm | 1/2in / 13mm | 610 | 175-215 / 132-160 | 49,060 / 22,300 |

| MCS1300 | 51 / Short Head | 4in / 102mm | 7/16in / 10mm | 610 | 175-215 / 132-160 | 49,060 / 22,300 |

| MCSS1300 | 51 / Ultra-Fine Shorthead | 2 3/4in / 70mm | 5/16in / 8mm | 610 | 175-215 / 132-160 | 49,060 / 22,300 |

| MCC1370 | 54 / Coarse Liner | 8 1/2in / 215mm | 3/4in / 19mm | 610 | 250-295 / 185-220 | 57,860 / 26,300 |

| MCF1370 | 54 / Fine Liner | 6 1/2in / 160mm | 5/8in / 16mm | 610 | 250-295 / 185-220 | 57,860 / 26,300 |

| MCS1370 | 54 / Short Head | 4 1/2in / 115mm | 1/2in / 13mm | 610 | 250-295 / 185-220 | 57,860 / 26,300 |

| MCSS1370 | 54 / Ultra-Fine Shorthead | 3in / 76mm | 5/16in / 8mm | 610 | 250-295 / 185-220 | 57,860 / 26,300 |

| MCC1500 | 60 / Coarse Liner | 9 1/4in / 235mm | 7/8in / 22mm | 560 | 250-300 / 185-225 | 83,050 / 37,750 |

| MCF1500 | 60 / Fine Liner | 6 3/4in / 175mm | 3/4in / 19mm | 560 | 250-300 / 185-225 | 83,050 / 37,750 |

| MCS1500 | 60 / Short Head | 5in / 130mm | 1/2in / 13mm | 560 | 250-300 / 185-225 | 83,050 / 37,750 |

| MCSS1500 | 60 / Ultra-Fine Shorthead | 3 1/2in / 90mm | 7/16in / 10mm | 560 | 250-300 / 185-225 | 83,050 / 37,750 |

| MCC1680 | 66 / Coarse Liner | 10 1/2in / 267mm | 7/8in / 22mm | 560 | 335-400 / 250-300 | 97,460 / 44,300 |

| MCF1680 | 66 / Fine Liner | 8in / 203mm | 5/8in / 16mm | 560 | 335-400 / 250-300 | 97,460 / 44,300 |

| MCS1680 | 66 / Short Head | 5 1/2in / 140mm | 1/2in / 13mm | 560 | 335-400 / 250-300 | 97,460 / 44,300 |

| MCSS1680 | 66 / Ultra-Fine Shorthead | 3 3/4in / 95mm | 7/16in / 10mm | 560 | 335-400 / 250-300 | 97,460 / 44,300 |

Capacity at closed side discharge opening size (in/mm)

| Model No. |

STPH/MTPH @ 1/4in / 6mm |

STPH/MTPH @ 7/16in / 10mm |

STPH/MTPH @ 1/2in / 13mm |

STPH/MTPH @ 5/8in / 16mm |

STPH/MTPH @ 3/4in / 19mm |

STPH/MTPH @ 7/8in / 22mm |

STPH/MTPH @ 1in / 25mm |

STPH/MTPH @ 1 1/2in / 38mm |

STPH/MTPH @ 2in / 51mm |

STPH/MTPH @ 2 1/2in / 64mm |

|---|---|---|---|---|---|---|---|---|---|---|

| MCC600 | - | 22/20 | 28/25 | 33/30 | 39/35 | 50/45 | 55/50 | 84/76 | - | - |

| MCF600 | 20/18 | 22/20 | 28/25 | 33/30 | 39/35 | 44/40 | 50/45 | 66/60 | - | - |

| MCC1000 | - | - | 88/80 | 110/100 | 149/135 | 165/150 | 193/175 | 259/235 | - | - |

| MCF1000 | - | 72/65 | 83/75 | 99/90 | 132/120 | 149/135 | 165/150 | - | - | - |

| MCS1000 | - | 57/52 | 68/62 | 79/72 | 86/78 | 127/115 | - | - | - | - |

| MCSS1000 | 55/50 | 61/55 | 72/65 | 77/70 | 112/102 | - | - | - | - | - |

| MCC1150 | - | - | 127/115 | 149/135 | 165/150 | 198/180 | 220/200 | 286/260 | - | - |

| MCF1150 | - | 110/100 | 121/110 | 132/120 | 149/135 | 182/165 | 193/175 | - | - | - |

| MCS1150 | - | 88/80 | 116/105 | 121/110 | 154/140 | - | - | - | - | - |

| MCSS1150 | 66/60 | 81/74 | 116/105 | 121/110 | 143/130 | - | - | - | - | - |

| MCC1300 | - | - | - | 165/150 | 198/180 | 220/200 | 253/230 | 341/310 | 429/390 | - |

| MCF1300 | - | - | 127/115 | 160/145 | 176/160 | 209/190 | 231/210 | - | - | - |

| MCS1300 | - | 99/90 | 127/115 | 154/140 | 176/160 | - | - | - | - | - |

| MCSS1300 | - | 97/88 | 121/110 | 149/135 | 171/155 | - | - | - | - | - |

| MCC1370 | - | - | - | - | 220/200 | 242/220 | 286/260 | 385/350 | 484/440 | - |

| MCF1370 | - | - | - | 171/155 | 198/180 | 220/200 | 242/220 | - | - | - |

| MCS1370 | - | - | 165/150 | 209/190 | 231/210 | 253/230 | - | - | - | - |

| MCSS1370 | - | 134/122 | 163/148 | 204/185 | 220/200 | - | - | - | - | - |

| MCC1500 | - | - | - | - | - | 292/265 | 341/310 | 462/420 | 578/525 | 638/580 |

| MCF1500 | - | - | - | - | 237/215 | 264/240 | 292/265 | 352/320 | - | - |

| MCS1500 | - | - | 198/180 | 231/210 | 259/235 | 281/255 | 303/275 | - | - | - |

| MCSS1500 | - | 163/148 | 196/178 | 220/200 | 242/220 | - | - | - | - | - |

| MCC1680 | - | - | - | - | - | 363/330 | 429/390 | 578/525 | 721/655 | 798/725 |

| MCF1680 | - | - | - | 253/230 | 297/270 | 330/300 | 363/330 | - | - | - |

| MCS1680 | - | - | 204/185 | 248/225 | 292/265 | 374/340 | - | - | - | - |

| MCSS1680 | - | 198/180 | 242/220 | 286/260 | 369/335 | - | - | - | - | - |

Capacity based on continuous regulated feed of clean, dry limestone of normal hardness with a bulk density of 1.6 ton/m3. Capacity may vary +/- 25% with the size and nature of the rock and the working conditions of the plant.

Weight of Main Parts (Ton)

| Size Part | 600 | 1000 | 1150 | 1300 | 1370 | 1500 | 1680 |

|---|---|---|---|---|---|---|---|

| Lower Body Group + Upper Frame | 2 | 5 | 7 | 11 | 13 | 17.6 | 21.75 |

| Upper Body Group - Upper Frame | 0.9 | 2.2 | 3.2 | 4.4 | 5.5 | 7.9 | 12.85 |

| Eccentric Seat Group | 0 | 1 | 0.65 | 1.1 | 1.25 | 2.1 | 2.3 |

| Eccentric Shaft Group | 0 | 1 | 2.1 | 3.1 | 3.75 | 5.9 | 7.4 |

| Transmission Shaft Group | 0 | 1 | 1 | 1 | 1 | 1.7 | 1.32 |

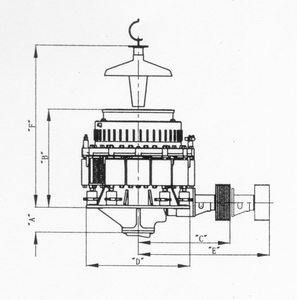

Dimensions (mm)

| Type | A | B | C | D | E | F |

|---|---|---|---|---|---|---|

| 600 | 13-1/2in 345mm | 45in 1146mm | 43-1/2in 1105mm | 49-1/4in 1250mm | 69in 1750mm | 75-1/2in 1920mm |

| 1000 | 15-1/2in 395mm | 61in 1554mm | 61in 1546mm | 60-1/4in 1530mm | 86-1/2in 2200mm | 110-1/4in 2800mm |

| 1150 | 20-1/2in 522mm | 66-1/2in 1690mm | 65-1/2in 1670mm | 69-1/4in 1760mm | 95in 2415mm | 118in 3000mm |

| 1300 | 24in 609mm | 76in 1927mm | 75-1/2in 1920mm | 79-1/2in 2020mm | 110in 2800mm | 137-3/4in 3500mm |

| 1370 | 24in 612mm | 84-3/4in 2151mm | 77in 1965mm | 86-1/2in 2200mm | 111-1/2in 2830mm | 153-1/2in 3900mm |

| 1500 | 28-3/4in 730mm | 93-1/2in 2372mm | 87-1/4in 2216mm | 96-1/2in 2450mm | 125in 3170mm | 169-1/4in 4300mm |

| 1680 | 34in 860mm | 86in 2183mm | 83in 2107mm | 112-1/2in 2860mm | 139-3/4in 3550mm | 185in 4700mm |

The parameters above are for reference only.

Have questions about what we do? Interested in our product or becoming a partner? The first step is to get in touch with us. Head to our Contact Page and connect with the office in your area.