Minyu MSP Series Cone Crusher

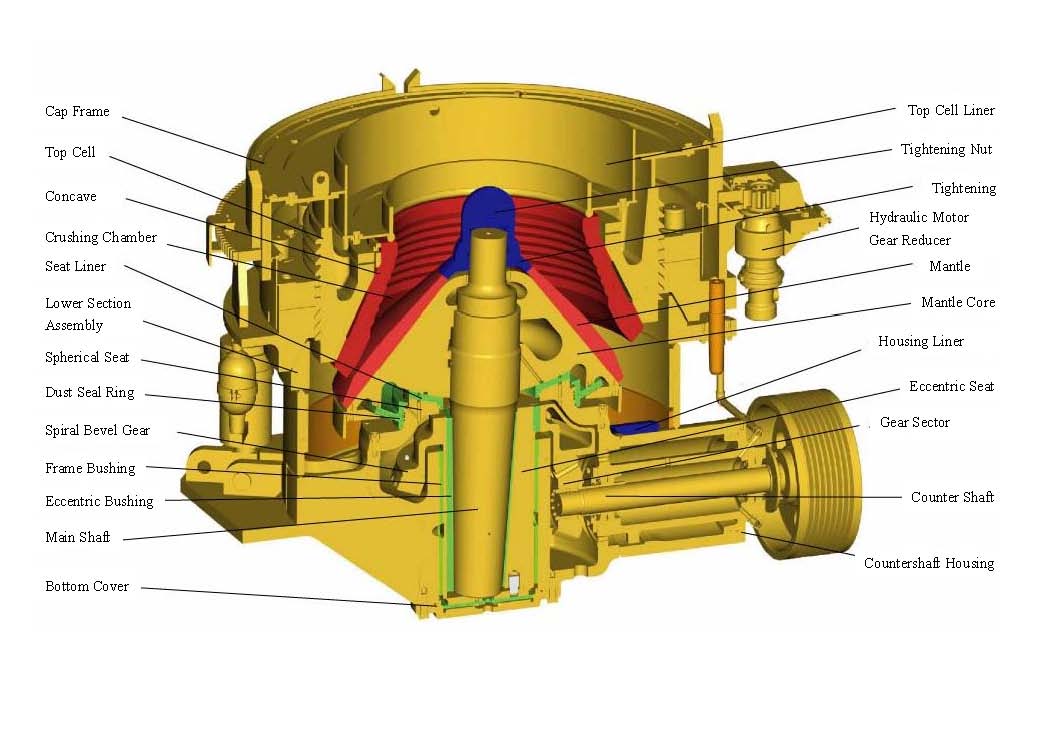

Features:

- High capacity product with perfect shape and even sizing.

- Stress relieved frame: Heavy duty reinforcements are installed at high stress points.

- Hydraulic Adjustment to aid in quick Cone Crusher setting changes.

- Hydraulic clearing is standard on SP Cone Crushers with release cylinders to shorten the down time.

- NO filling in the concave to be replaced quickly and expediently.

- Automatic overload protection: If overloaded, the crusher can be restored automatically to keep the discharge opening and steady productive qualities.

- SP Cone Crushers have a high capacity, external mounted lubrication pump, oil tank, oil filtering system, high oil temperature shut-down, low oil flow shut downs and an oil flow gauge. A heat exchanger is also available.

- Higher eccentric height for bigger crushing ratio and higher crushing efficiency.

- Concave locked to top cell from above, stable fixation, easy exchange.

- Higher rotation speed up to 800 rpm for higher capacity.

- Increased height of mantle & concave for more crushing efficiency.

- Increased stroke at the feed opening for higher crushing ratio and more throughput.

- Strong & tidy main frame, crusher sheave with high power transmission rate, for longer service life of the drive device.

| Model No. | Size (in/type) | Max Feed Opening (in/mm) | Min Discharge Opening (in/mm) | Motor Power (HP/kW) | Weight (lbs/kg) |

|---|---|---|---|---|---|

| MSP100 (C) | 31 / Coarse Liner | 5in / 135mm | 5/8in / 16mm | 100-150 / 75-112 | 14,960 / 6,800 |

| MSP100 (M) | 31 / Fine Liner | 4in / 105mm | 5/8in / 16mm | 100-150 / 75-112 | 14,960 / 6,800 |

| MSP200 (C) | 40 / Coarse Liner | 7in / 185mm | 3/4in / 19mm | 150-200 / 110-150 | 26,400 / 12,000 |

| MSP200 (M) | 40 / Fine Liner | 6in / 145mm | 2/3in / 17mm | 150-200 / 110-150 | 26,400 / 12,000 |

| MSP200 (F) | 40 / Short Head Liner | 2 3/4in / 70mm | 1/2in / 13mm | 150-200 / 110-150 | 26,400 / 12,000 |

| MSP300 (C) | 48 / Coarse Liner | 8 1/2in / 210mm | 4/5in / 22mm | 250-300 / 180-225 | 41,140 / 18,700 |

| MSP300 (M) | 48 / Fine Liner | 7in / 185mm | 3/4in / 19mm | 250-300 / 180-225 | 41,140 / 18,700 |

| MSP300 (F) | 48 / Short Head Liner | 3 1/2in / 90mm | 5/8in / 16mm | 250-300 / 180-225 | 41,140 / 18,700 |

| MSP400 (C) | 54 / Coarse Liner | 11 1/2in / 290mm | 5/8in / 16mm | 300-400 / 220-300 | 62,480 / 28,400 |

| MSP400 (M) | 54 / Fine Liner | 8 1/2in / 210mm | 4/5in / 22mm | 300-400 / 220-300 | 62,480 / 28,400 |

| MSP400 (F) | 54 / Short Head Liner | 4 1/2in / 110mm | 5/8in / 16mm | 300-400 / 220-300 | 62,480 / 28,400 |

Capacity at closed side discharge opening size (in/mm)

| Model No. |

TPH @ 1/2in / 13mm |

TPH @ 5/8in / 16mm |

TPH @ 3/4in / 19mm |

TPH @ 7/8in / 22mm |

TPH @ 1in / 25mm |

TPH @ 1-1/4in / 32mm |

TPH @ 1-1/2in / 38mm |

TPH @ 1-3/4in / 45mm |

TPH @ 2in / 51mm |

|---|---|---|---|---|---|---|---|---|---|

| MSP100 (C) | - | 75-85 | 80-95 | 85-100 | 90-110 | 100-130 | - | - | - |

| MSP100 (M) | 40-60 | 55-70 | 65-80 | 70-85 | 75-95 | 90-110 | - | - | - |

| MSP200 (C) | - | - | - | 180-210 | 200-240 | 235-270 | 265-310 | - | - |

| MSP200 (M) | - | - | 145-165 | 160-195 | 185-220 | 210-245 | 230-280 | - | - |

| MSP200 (F) | 90-110 | 105-125 | 120-135 | 125-140 | 130-150 | 140-165 | - | - | - |

| MSP300 (C) | - | - | - | 210-240 | 230-280 | 270-320 | 290-350 | 320-380 | 360-430 |

| MSP300 (M) | - | - | 190-220 | 205-230 | 225-260 | 245-285 | 270-330 | 300-350 | - |

| MSP300 (F) | - | 135-155 | 150-170 | 165-185 | 180-200 | 200-220 | - | - | - |

| MSP400 (C) | - | - | - | - | 295-355 | 335-375 | 370-480 | 430-500 | 470-550 |

| MSP400 (M) | - | - | - | 265-310 | 290-330 | 315-360 | 350-410 | 390-440 | - |

| MSP400 (F) | - | 155-185 | 175-220 | 195-225 | 210-245 | 235-256 | - | - | - |

Capacity based on continuous regulated feed of clean, dry limestone of normal hardness with a bulk density of 1.6 ton/m3. Capacity may vary +/- 25% with the size and nature of the rock and the working conditions of the plant.

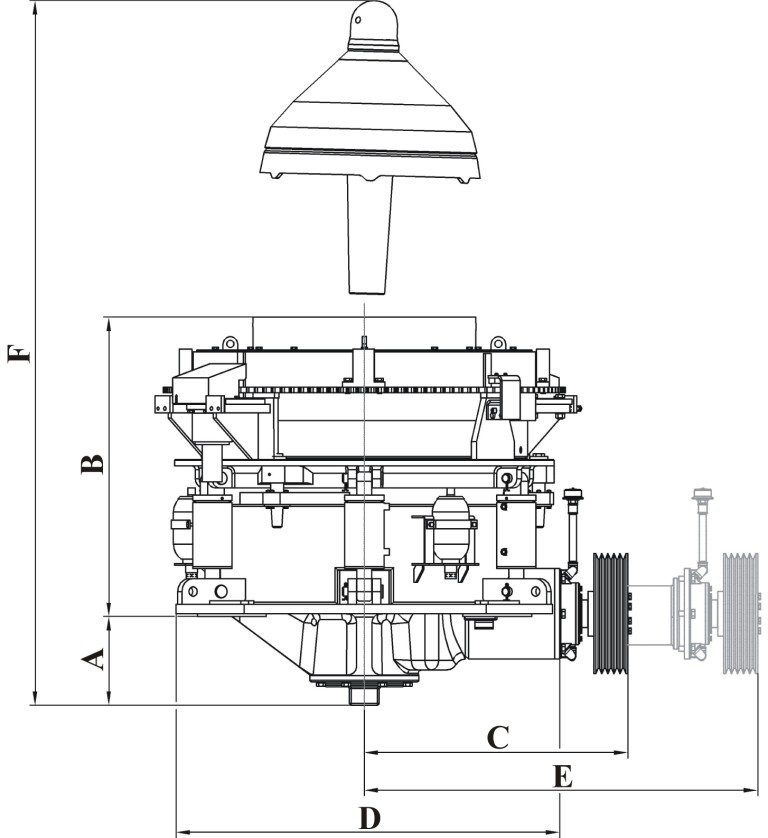

Dimensions (in/mm)

| Model No. | A | B | C | D | E | F |

|---|---|---|---|---|---|---|

| MSP100 | 10in / 264mm | 44in / 1119mm | 42in / 1060mm | 57in / 1450mm | 63in / 1610mm | 105 in / 2667mm |

| MSP200 | 17 in / 423mm | 57in / 1445mm | 50in / 1255mm | 71in / 1808mm | 82in / 2075mm | 116in / 2945mm |

| MSP300 | 16in / 403mm | 62in / 1583mm | 58in / 1471mm | 84in / 2126mm | 95in / 2407mm | 128in / 3252mm |

| MSP400 | 19in / 477mm | 70in / 1770mm | 68in / 1717mm | 99in / 2505mm | 109in / 2780mm | 147in / 3727mm |

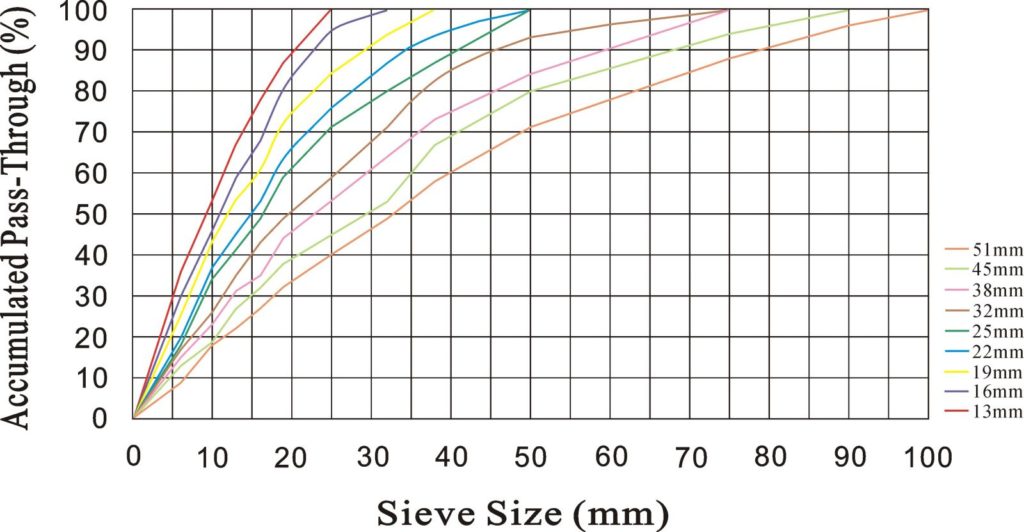

| Sieve Size | 13mm | 16mm | 19mm | 22mm | 25mm | 32mm | 38mm | 45mm | 51mm |

|---|---|---|---|---|---|---|---|---|---|

| 90mm | - | - | - | - | - | - | - | 100 | 96-100 |

| 75mm | - | - | - | - | - | 100 | 100 | 93-95 | 87-89 |

| 50mm | - | - | - | 100 | 100 | 92-95 | 83-86 | 79-82 | 70-72 |

| 38mm | - | - | 100 | 94-97 | 86-89 | 83-86 | 72-75 | 66-69 | 57-59 |

| 32mm | - | 100 | 92-95 | 86-89 | 79-82 | 70-73 | 63-66 | 52-55 | 48-51 |

| 25mm | 100 | 93-97 | 83-85 | 75-78 | 70-73 | 58-61 | 52-55 | 44-47 | 39-41 |

| 19mm | 84-89 | 79-83 | 71-74 | 63-66 | 58-61 | 48-51 | 43-46 | 37-40 | 31-33 |

| 16mm | 76-80 | 66-70 | 59-62 | 52-55 | 48-51 | 42-45 | 34-37 | 31-33 | 26-28 |

| 13mm | 65-70 | 56-62 | 52-55 | 43-48 | 40-43 | 34-37 | 30-33 | 26-29 | 21-23 |

| 10mm | 52-55 | 45-48 | 42-45 | 36-39 | 33-36 | 25-28 | 22-25 | 18-20 | 17-19 |

| 6mm | 34-39 | 28-32 | 23-28 | 19-22 | 17-20 | 16-18 | 14-16 | 12-14 | 8-10 |

Have questions about what we do? Interested in our product or becoming a partner? The first step is to get in touch with us. Head to our Contact Page and connect with the office in your area.