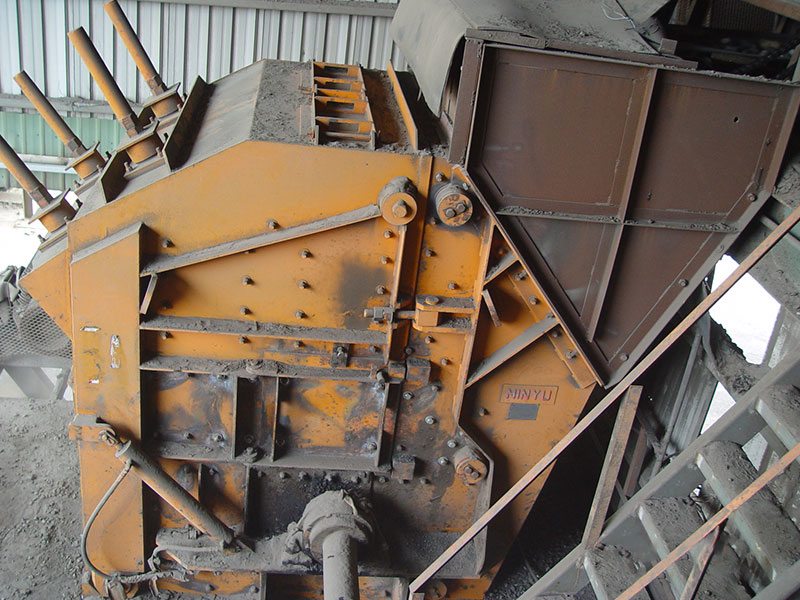

MIC Horizontal Shaft Impact Crusher

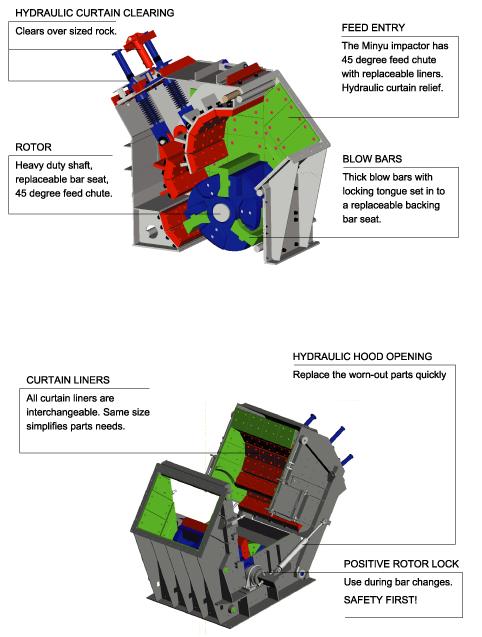

Features:

- Has taken a patent in U.S.A.

- Three-Four Rows of Blow Bars.

- Extra large Feed Opening

- Rotor Assembly equipped with anti skid device.

- Hammers with balanced counterweight

- Chrome Moly Shaft.

- Dual adjustable Curtains.

- Hydraulic Hood Opening.

- 150mm Bearing. Automatic adjustment Control.

- 45 degree Feed Chute with replaceable Liners.

- Solid Main Frame with heat treatment.

| Type | Working Diameter of Rotor (in/mm) | Effective Width of Rotor (in/mm) | Feed Opening LxW (in/mm) | Power (HP/kW) | Weight (lbs/kg) |

|---|---|---|---|---|---|

| MIC102092 | 40 / 1,020 | 36 / 914 | 36x31 / 930x800 | 75-100 / 55-75 | 22,600 / 10,300 |

| MIC102115 | 40 / 1,020 | 45 / 1,143 | 45x31 / 1,160x800 | 120-150 / 90-110 | 25,300 / 11,500 |

| MIC102152 | 40 / 1,020 | 60 / 1,524 | 60x31 / 1,540x800 | 150-175 / 110-132 | 29,370 / 13,350 |

| MIC133076 | 52 / 1,330 | 30 / 762 | 30x42 / 778x1,065 | 75-100 / 55-75 | 25,080 / 11,400 |

| MIC133092 | 52 / 1,330 | 36 / 914 | 36x42 / 930x1,065 | 120-150 / 90-110 | 30,580 / 13,900 |

| MIC133115 | 52 / 1,330 | 45 / 1,143 | 45x42 / 1,160x1,065 | 175-215 / 132-160 | 35,200 / 16,000 |

| MIC133152 | 52 / 1,330 | 60 / 1,524 | 60x42 / 1,540x1,065 | 250-300 / 185-220 | 42,900 / 19,500 |

| MIC133184 | 52 / 1,330 | 72 / 1,848 | 73x42 / 1,844x1,065 | 250-300 / 185-220 | 48,400 / 22,000 |

All parameters are for reference only & subject to change without notice.

Capacity at closed side discharge opening size (in/mm)

| Type | TPH @ 3/4in / 19mm | TPH @ 1in / 25mm | TPH @ 1 1/2in / 38mm | TPH @ 2in / 51mm | TPH @ 2 1/2in / 63mm | TPH @ 3in / 76mm |

|---|---|---|---|---|---|---|

| MIC102092 | 60 | 80 | 94 | 110 | 120 | 135 |

| MIC102115 | 75 | 100 | 120 | 137 | 150 | 170 |

| MIC102152 | 95 | 116 | 145 | 160 | 186 | 215 |

| MIC133076 | 76 | 102 | 121 | 140 | 152 | 173 |

| MIC133092 | 92 | 124 | 145 | 169 | 184 | 209 |

| MIC133115 | 116 | 155 | 184 | 211 | 230 | 261 |

| MIC133152 | 193 | 254 | 303 | 344 | 382 | 422 |

| MIC133184 | 250 | 330 | 394 | 448 | 496 | 548 |

Capacity based on continuous regulated feed of clean, dry limestone of normal hardness with a bulk density of 1.6 ton/m3. Capacity may vary with the size and nature of the rock and the working conditions of the plant.

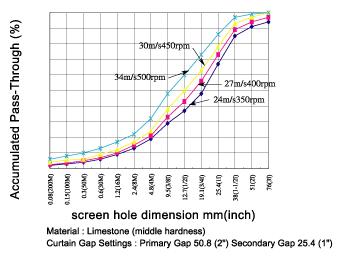

Grading of Size (Pass-Through Percentage)

| Size (in/mm) | 24m/s | 27m/s | 30m/s | 34m/s |

|---|---|---|---|---|

| 3in / 76mm | 94 | 97 | 100 | 100 |

| 2in / 51mm | 91 | 94 | 97 | 99 |

| 1 1/2in / 38mm | 85 | 89 | 93 | 97 |

| 1in / 25.4mm | 67 | 73 | 78 | 86 |

| 3/4in / 19.1mm | 48 | 56 | 63 | 73 |

| 1/2in / 12.7mm | 37 | 43 | 50 | 60 |

| 3/8in / 9.5mm | 29 | 33 | 38 | 48 |

| 4M / 4.8mm | 19 | 21 | 24 | 32 |

| 8M / 2.4mm | 13 | 15 | 17 | 22 |

| 16M / 1.2mm | 9 | 10 | 12 | 17 |

| 30M / 0.6mm | 6 | 7 | 9 | 13 |

| 50M / 0.3mm | 4 | 5 | 6 | 10 |

| 100M / 0.15mm | 3 | 3.5 | 5.5 | 8 |

| 200M / 0.08mm | 2 | 2.5 | 4 | 6 |

Capacity based on continuous regulated feed of clean, dry limestone of normal hardness with a bulk density of 1.6 ton/m3. Capacity may vary +/- 25% with the size and nature of the rock and the working conditions of the plant.

All parameters are for reference only & subject to change without notice.

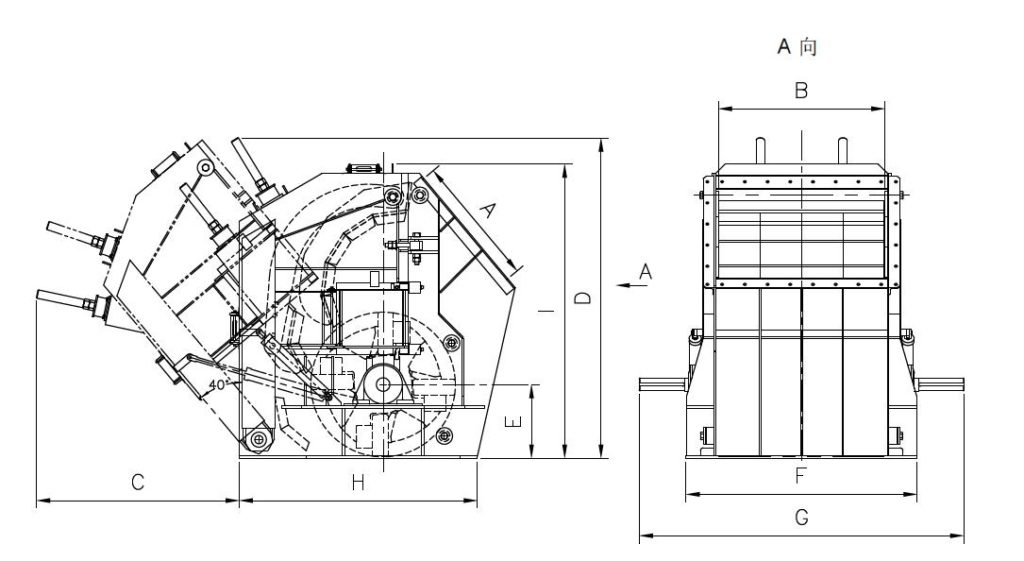

Dimensions (in/mm)

| Type | A | B | C | D | E | F | G | H | I |

|---|---|---|---|---|---|---|---|---|---|

| MIC102092 | 800 | 930 | 1493 | 2400 | 509 | 1525 | 2210 | 1790 | 2055 |

| MIC102115 | 800 | 1160 | 1488 | 2382 | 509 | 1755 | 2430 | 1790 | 2055 |

| MIC102152 | 800 | 1540 | 1507 | 2355 | 509 | 2135 | 2750 | 1790 | 2055 |

| MIC133076 | 1059 | 778 | 1851 | 2944 | 679 | 1372 | 2050 | 2200 | 2676 |

| MIC133092 | 1065 | 930 | 1851 | 2928 | 679 | 1524 | 2210 | 2200 | 2686 |

| MIC133115 | 1065 | 1160 | 1851 | 2944 | 679 | 1754 | 2430 | 2200 | 2686 |

| MIC133152 | 1142 | 1540 | 1890 | 2928 | 679 | 2134 | 2830 | 2200 | 2676 |

| MIC133184 | 1065 | 1844 | 1851 | 2927 | 679 | 2438 | 3130 | 2200 | 2676 |

All parameters are for reference only & subject to change without notice.

Have questions about what we do? Interested in our product or becoming a partner? The first step is to get in touch with us. Head to our Contact Page and connect with the office in your area.