Minyu MS Type Jaw Crusher

The Minyu MS Type Jaw Crusher is recommended for concrete recycling, river stones, tough ores, and other large lumps.

Features:

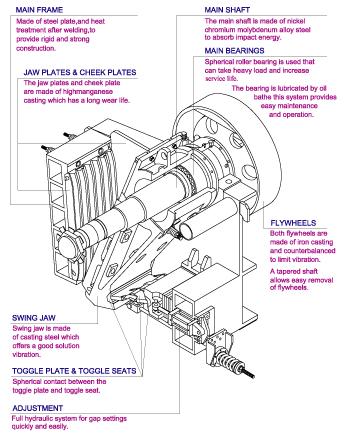

- Top quality roller bearings provide strength & safety. Oil bath lubrication ensures longer service life.

- Toggle plate, toggle block, and toggle seat protect the crusher from damage caused by uncrushable material in the crushing chamber. This construction helps to maintain a stable crushing angle.

- Simple & quick discharge gap adjustment, precise product grain distribution.

- Large & deep crushing chamber with sharp crushing angle, to achieve a very high crushing ratio.

- The MS-Model with bigger feed opening and longer pitman arm is especially suitable for primary crushing.

- Recommended for big lumps & large quantities, for primary crushing of limestone, river stone, tough ores, and concrete recycling.

| Model No. | Feed Opening LxW (in/mm) | RPM | Motor Power (HP/kW) | Approx. Weight (lbs/kg) |

|---|---|---|---|---|

| MS2416 | 24x16 / 600x400 | 275 | 40-55 / 30-40 | 14,080 / 6,400 |

| MS3020 | 30x20 / 750x500 | 250 | 60-80 / 45-60 | 20,460 / 9,300 |

| MS3624 | 36x24 / 900x600 | 250 | 80-100 / 60-75 | 31,020 / 14,100 |

| MS4226 | 42x26 / 1050x650 | 260 | 100-120 / 75-90 | 37,840 / 17,200 |

| MS4230 | 42x30 / 1050x750 | 230 | 120-155 / 90-115 | 45,100 / 20,500 |

| MS4832 | 48x32 / 1200x800 | 230 | 155-200 / 115-150 | 58,630 / 26,650 |

| MS4840 | 48x40 / 1200x1000 | 200 | 175-200 / 130-150 | 99,000 / 45,000 |

| MS5432 | 54x32 / 1350x800 | 200 | 180-200 / 135-150 | 60,600 / 27,550 |

| MS6040 | 60x40 / 1500x1000 | 200 | 250-300 / 185-225 | 110,440 / 50,200 |

| MS6048 | 60x48 / 1500x1200 | 190 | 250-350 / 185-265 | 162,140 / 73,700 |

All parameters are for reference only & subject to change without notice.

Capacity at closed side discharge opening size (in/mm)

| Model No. |

STPH/MTPH@ 2in/50mm |

STPH/MTPH@ 2 3/4in / 70mm |

STPH/MTPH@ 3in / 80mm |

STPH/MTPH@ 4in / 100mm |

STPH/MTPH@ 5in / 125mm |

STPH/MTPH@ 6in / 150mm |

STPH/MTPH@ 8in / 200mm |

STPH/MTPH@ 9in / 225mm |

STPH/MTPH@ 10in / 250mm |

STPH/MTPH@ 12in / 300mm |

|---|---|---|---|---|---|---|---|---|---|---|

| MS2416 | 29 / 26 | 42 / 38 | 50 / 45 | 66 / 60 | 83 / 75 | - | - | - | - | - |

| MS3020 | 44 / 40 | 66 / 60 | 77 / 70 | 99 / 90 | 123 / 112 | 143 / 130 | - | - | - | - |

| MS3624 | - | - | 116 / 105 | 143 / 130 | 176 / 160 | 200 / 182 | - | - | - | - |

| MS4226 | - | - | - | 165 / 150 | 198 / 180 | 226 / 205 | 281 / 255 | - | - | - |

| MS4230 | - | - | - | 198 / 180 | 231 / 210 | 261 / 237 | 323 / 294 | - | - | - |

| MS4832 | - | - | - | 231 / 210 | 275 / 250 | 308 / 280 | 352 / 320 | 385 / 350 | - | - |

| MS4840 | - | - | - | - | 292 / 265 | 332 / 302 | 407 / 370 | 442 / 402 | - | - |

| MS5432 | - | - | - | 275 / 250 | 330 / 300 | 374 / 340 | 462 / 420 | 495 / 450 | - | - |

| MS6040 | - | - | - | - | 341 / 310 | 385 / 350 | 484 / 440 | 528 / 480 | 561 / 510 | - |

| MS6048 | - | - | - | - | - | 457 / 415 | 550 / 500 | 594 / 540 | 638 / 580 | 693 / 630 |

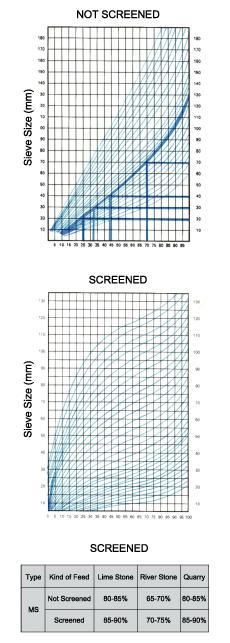

Capacity based on continuous regulated feed of clean, dry limestone of normal hardness with a bulk density of 1.6 ton/m3. Capacity may vary +/- 25% with the size and nature of the rock and the working conditions of the plant.

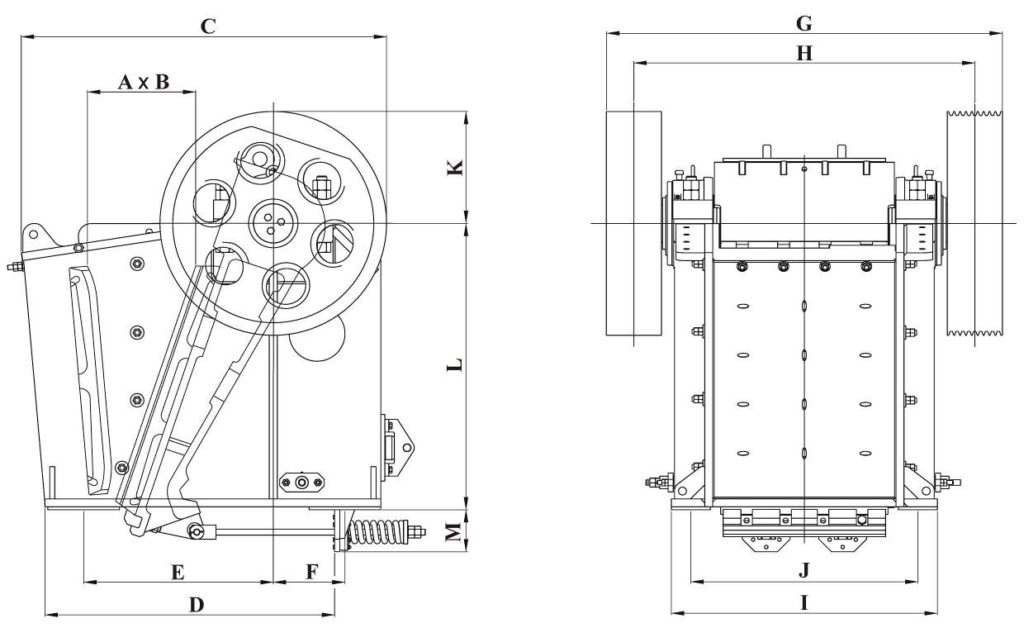

Dimensions (mm)

| Model No. | A | B | C | D | E | F | G | H | I | J | K | L | M |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MS2416 | 23-3/4in 600mm | 15-3/4in 400mm | 61in 1550mm | 57-1/2in 1462mm | 30-1/4in 770mm | 15-1/2in 390mm | 60-1/2in 1534mm | 52-3/4in 1340mm | 42-1/2in 1080mm | 38-1/4in 970mm | 19in 485mm | 45-3/4in 1160mm | 7in 175mm |

| MS3020 | 29-1/2in 750mm | 19-3/4in 500mm | 65-1/2in 1660mm | 61-1/2in 1562mm | 34-1/4in 870mm | 15-1/2in 390mm | 68-1/4in 1732mm | 60-1/2in 1534mm | 50in 1270mm | 45-1/4in 1150mm | 23-3/4in 601mm | 50in 1270mm | 7in 180mm |

| MS3624 | 35-1/2in 900mm | 23-3/4in 600mm | 75-1/4in 1910mm | 70-1/2in 1793mm | 39in 990mm | 15-3/4in 400mm | 81-1/4in 2066mm | 72in 1830mm | 59in 1500mm | 53-1/2in 1360mm | 26-1/2in 671mm | 59-3/4in 1515mm | 9-1/2in 240mm |

| MS4226 | 41-1/2in 1050mm | 25-1/2in 650mm | 86in 2185mm | 81in 2058mm | 36-1/2in 934mm | 18in 456mm | 91-3/4in 2330mm | 78in 1980mm | 65-1/2in 1660mm | 59-1/2in 1510mm | 23-3/4in 600mm | 65-1/2in 1591mm | 3-1/4in 82mm |

| MS4230 | 41-1/2in 1050mm | 29-1/2in 750mm | 89-3/4in 2280mm | 84-1/2in 2142mm | 46-3/4in 1190mm | 17-3/4in 450mm | 98in 2486mm | 84-1/2in 2144mm | 69in 1750mm | 61in 1550mm | 28in 711mm | 71-1/2in 1820mm | 10-1/2in 266mm |

| MS4832 | 47-1/4in 1200mm | 31-1/2in 800mm | 96-3/4in 2460mm | 91-1/4in 2319mm | 54in 1370mm | 17-3/4in 450mm | 105-3/4in 2686mm | 92-1/2in 2344mm | 74-3/4in 1900mm | 67in 1700mm | 28in 711mm | 71-1/2in 1820mm | 10-1/2in 265mm |

| MS4840 | 47-1/4in 1200mm | 39-1/2in 1000mm | 116-1/4in 2950mm | 108-3/4in 2765mm | 60-3/4in 1545mm | 24-1/2in 620mm | 1117-1/4in 2978mm | 102-3/4in 2610mm | 80-1/4in 2040mm | 71-1/2in 1820mm | 39-1/4in 994mm | 93-1/2in 2370mm | 13-3/4in 350mm |

| MS5432 | 53-1/4in 1350mm | 31-1/2in 800mm | 94-1/2in 2400mm | 89in 2259mm | 51-1/2in 1310mm | 17-3/4in 450mm | 111-1/2in 2836mm | 98in 2490mm | 80-3/4in 2050mm | 72-3/4in 1850mm | 28in 711mm | 72-1/2in 1840mm | 10-1/2in 265mm |

| MS6040 | 59in 1500mm | 39-1/2in 1000mm | 116-1/4in 2950mm | 108-3/4in 2765mm | 60-3/4in 1540mm | 24-1/2in 620mm | 128-3/4in 3248mm | 113-1/2in 2880mm | 92-1/2in 2340mm | 83-1/2in 2120mm | 39-1/4in 994mm | 92-1/2in 2350mm | 12-1/2in 320mm |

| MS6048 | 59in 1500mm | 47-1/4in 1200mm | 143-1/2in 3640mm | 133in 3380mm | 72in 1830mm | 28-3/4in 730mm | 139in 3532mm | 122-3/4in 3120mm | 96-1/2in 2450mm | 87-1/2in 2220mm | 41-1/4in 1044mm | 111-1/2in 2830mm | 6-3/4in 170mm |

All parameters are for reference only & subject to change without notice.

Have questions about what we do? Interested in our product or becoming a partner? The first step is to get in touch with us. Head to our Contact Page and connect with the office in your area.